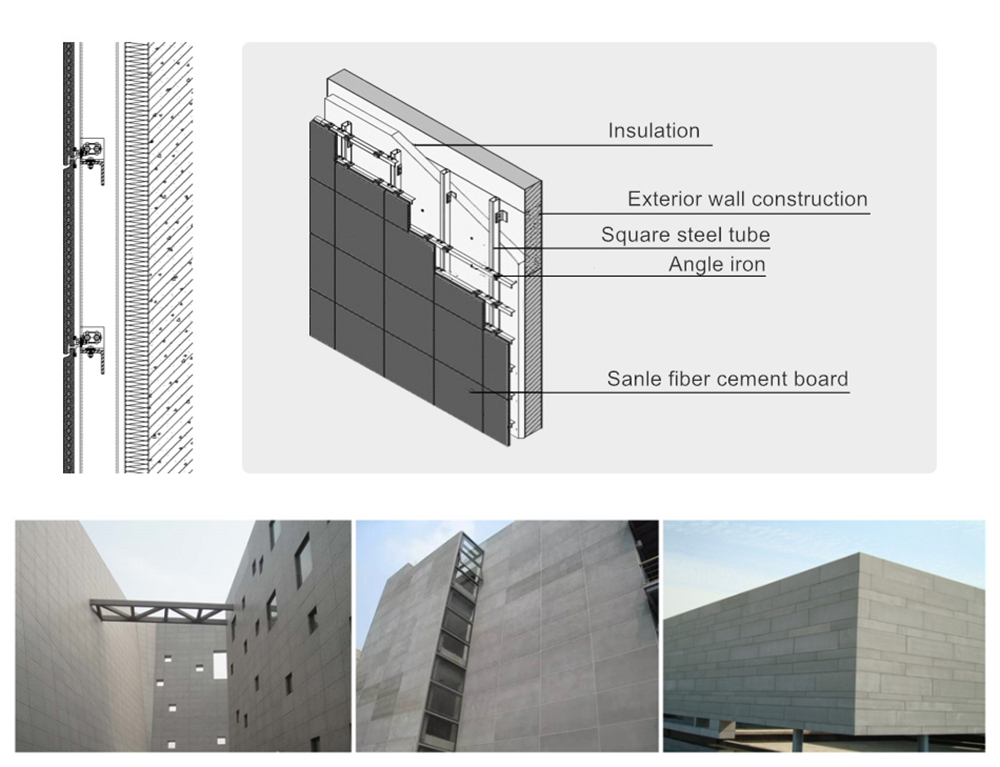

Exterior Wall Installation of Fiber Cement Boards

Fiber cement boards offer a unique blend of beauty, resilience, and versatility, making them ideal for enhancing the appearance of any structure.

By installing fiber cement boards, you can enhance the beauty and durability of your exterior walls.

When you plan to use fiber cement boards to achieve the perfect exterior installation, you may want to follow these guidelines.

Preparation

● Surface Inspection: Thoroughly inspect the exterior wall surface to ensure it is clean, dry, and free from any debris, dirt, or loose paint.

● Structural Assessment: Evaluate the structural integrity of the wall and make any necessary repairs to address cracks, holes, or other damages.

● Weather Considerations: Choose a suitable weather window for installation to avoid adverse weather conditions during the process.

Materials and Tools

● Fiber Cement Boards: Select high-quality fiber cement boards that match your design preferences and exterior aesthetics.

● Fasteners: Opt for corrosion-resistant screws or nails specifically designed for fiber cement board installation.

● Cutting Tools: Use a circular saw with a fiber cement cutting blade for precise board cutting.

● Adhesive: Choose a recommended adhesive for securing the boards to the wall.

● Measuring Tools: Utilize a tape measure, level, and chalk line for accurate board alignment.

Exterior Wall Installation

1. Fiber Cement Board Preparation

According to the size and design requirements, install the supporting aluminum accessories( six aluminum accessories per sheet) on the back of the fiber cement board ( maximum cross-section size is 2780 * 1220 mm).

Making a cross line according to the vertical distance ( 600 mm ) between the transverse keels and the length of the fiber cement board uniform size, then fixing supporting aluminum fasteners at the intersection, using 10 mm long and 4 mm thick stainless steel screws.

2. Construction Wall Preparation

Cleaning up the wall surface, and then marking out the position lines and partition lines of the steels according to the design drawings and actual needs.

3. Wire Hanging

Vertical wire hanging should use the ∮1.0-∮1.2 size steel wire, with 8-10 kgs weight lower counterweight iron, and the upper end is hung on the special wire hanging Angle iron frame. The angle iron frames are fixed on the top corners of the wall with expansion bolts, and marking on the top and bottom of the control line.

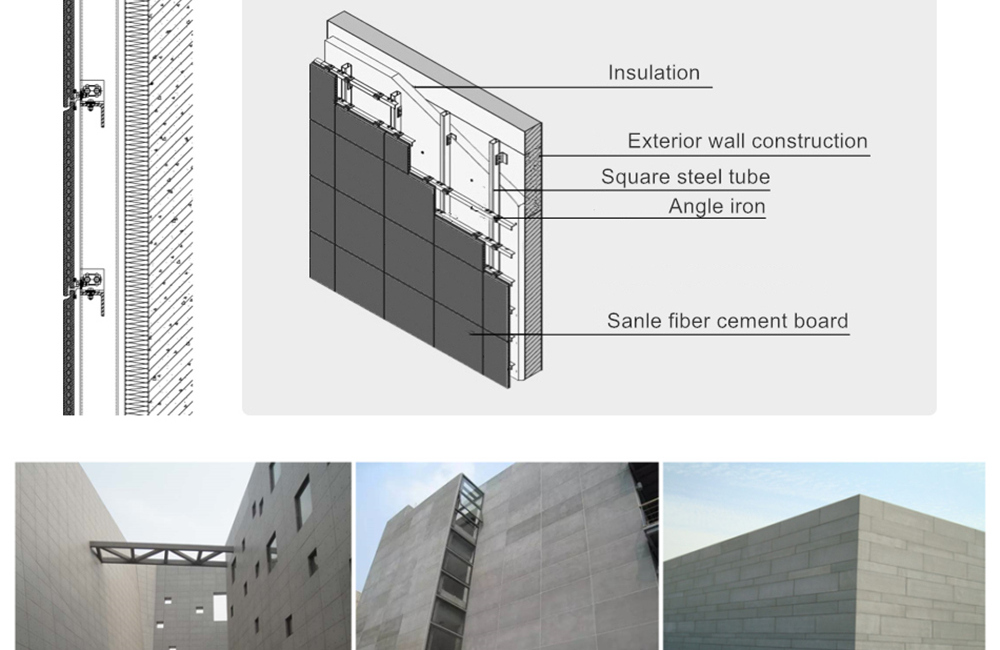

4. Keel Installation

First fixing 50×50×4 angle iron (with adjustable hole) on the structural surface with ∮8 expansion bolts, the horizontal distance between the angle iron and the 50×50×3.5 vertical square steel tube on the angle steel is 800mm.

When installing the vertical square steel tube, it must be checked by hanging steel wire from top to bottom to detect its Perpendicularity. After that, install the fastening angle iron and the transverse aluminum keel (with 600mm spacing).

The connection between the angle iron, square steel tube, and the transverse keel is made with ∮10 bolts. Last, use the infrared level meter to detect whether the horizontal aluminum keel is horizontal, and the steel line to detect whether it is vertical.

5. Fiber Cement Board Installation

Mounting the advanced processing board on the keel according to the design drawings, and using aluminum accessories to connect the panel and keel. Hanging lightly the same level layer of fiber cement boards on the keel, and then adjusting the horizontal and vertical degree of the board through upper and lower steel wires. After that, check the board's seam, whose width should be uniform according to the requirements of the design. Last, tighten the stainless steel screws (20mm long and 6mm thick) on the complete set of aluminum accessories.

6. Board Joint Treatment

Using the fiber cement board powder mixing glue to fill the seam, and then painting with a special coating twice. When filling the gap, it is necessary to pay attention to the uniform and full filling.

Maintenance

● Regular Inspection: Periodically inspect the fiber cement boards for any signs of damage, moisture penetration, or deterioration.

● Cleaning: Clean the boards as needed using mild detergent and water to maintain their original appearance.

● Repairs: Promptly address any issues such as cracks or loose boards to prevent further damage.

Transform your facade into a durable and stylish one by precisely installing fiber cement boards that enhance your property's visual appeal while ensuring long-lasting protection from the elements. Carefully reading the installation guidelines as well as consulting a professional if necessary will help you accomplish the perfect installation.