How Long Does Calcium Silicate Board Typically Last?

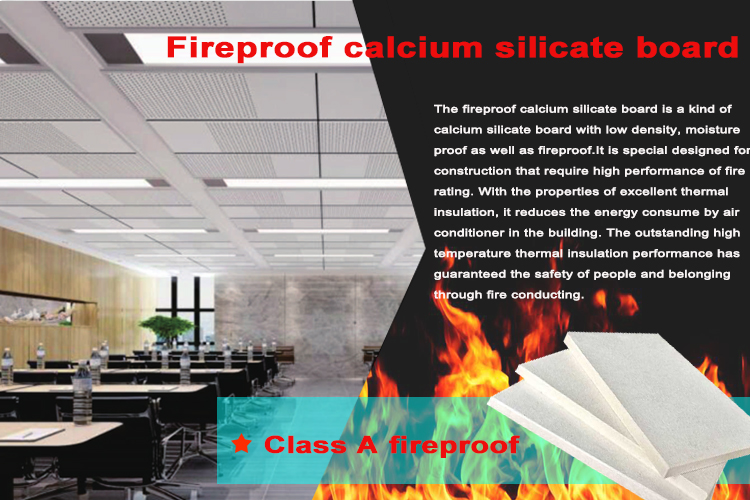

Fireproof calcium silicate board is a widely used building material known for its durability, versatility, and exceptional properties. It has gained popularity in various construction applications due to its resistance to fire, moisture, and impact.

Features of Fireproof Calcium Silicate Board

● Low-density and ultra-lightweight

● High fire resistance. The product can withstand 1200℃

● Resistance to deformation

● Excellent fireproof performance

● Easy processing

● Eco-friendly

● Mold and insect prevention

Application of Fireproof Calcium Silicate Board

Sanle fireproof calcium silicate board is for moisture proof, fire prevention, partition, ceiling, and other purposes in the relatively wet setting. It is widely used in offices, hotels, hospitals, factory buildings, schools, villas, theaters, and various art buildings.

How Long Does Calcium Silicate Board Typically Last?

When properly installed and maintained, calcium silicate boards have a long lifespan. On average, these boards can last anywhere between 20 to 30 years or more, depending on various factors.

However, it is important to note that this estimate can vary based on specific conditions and usage patterns.

Factors Influencing the Lifespan of Calcium Silicate Board

Installation Quality

The installation process plays a vital role in determining the lifespan of calcium silicate boards. It is crucial to ensure that the boards are installed following calcium silicate board manufacturers' guidelines and industry best practices. Proper attachment, sealing, and joint treatment are essential to maximize the board's performance and longevity.

Environmental Conditions

The environmental conditions to which calcium silicate boards are exposed can significantly impact their lifespan. Exposure to extreme temperatures, high humidity, excessive moisture, or prolonged sunlight can lead to degradation over time. It is important to assess the specific environmental conditions of the installation site and choose appropriate board grades or take necessary protective measures.

Maintenance of Fireproofing and Insulation Properties

Calcium silicate boards are often used for their fireproofing and insulation capabilities. It is important to ensure that these properties are maintained over time. Regular inspections should be conducted to assess the fire resistance and insulation performance of the boards. In case of any damage or degradation, appropriate measures should be taken to restore or replace the affected sections.

Structural Movement

Structural movements, such as settling, vibrations, or seismic activity, can impact the longevity of calcium silicate boards. Continuous or excessive movement can lead to cracks or dislodgement of the boards, compromising their performance. Proper structural design, including the use of expansion joints and accommodating movement, can help mitigate the impact of structural stresses.

Maintenance and Care

Regular maintenance and appropriate care can prolong the lifespan of calcium silicate boards. Routine inspections should be conducted to identify any signs of damage or deterioration. Prompt repairs, if needed, should be carried out to prevent further deterioration. Regular cleaning and appropriate surface treatments can help maintain the board's integrity and extend its lifespan.

Conclusion

Calcium silicate boards have a commendable lifespan, typically ranging from 20 to 30 years or more. However, various factors can impact their longevity, including installation quality, environmental conditions, maintenance and care, structural movement, and the preservation of fireproofing and insulation properties.

By understanding these factors and taking appropriate measures, such as proper installation, regular maintenance, and adherence to manufacturer guidelines, one can ensure that calcium silicate boards serve their intended purpose effectively and last for their expected lifespan.