Precautions for Using Calcium Silicate Boards

have become increasingly popular in construction and renovation projects due to their excellent fire-resistant properties and durability. These versatile building materials are commonly used for various applications.

What Are Calcium Silicate Boards Used For?

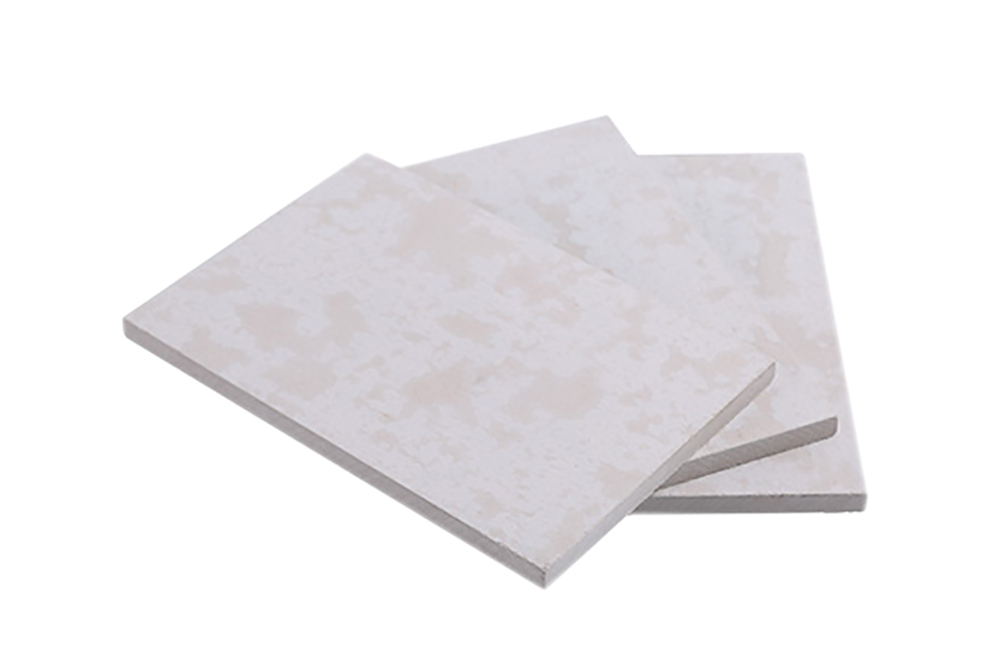

Calcium silicate boards are versatile construction materials made from a combination of cement, silica, and reinforcing fibers. They are commonly used for applications such as partition walls, ceilings, cladding, and fire protection due to their excellent fire resistance, durability, and thermal insulation properties.

Precautions for Using Calcium Silicate Board

It's crucial to take certain precautions when working with calcium silicate boards to ensure safety and achieve optimal results.

Personal Protective

When working with calcium silicate boards, it is important to wear personal protective equipment such as safety goggles, gloves, dust masks, and protective clothing to minimize the risk of injury.

Proper Handling and Storage

Ensure that you handle calcium silicate boards with care to prevent damage and maintain their integrity. Avoid dropping or mishandling the boards, as they can crack or break, compromising their structural strength. Additionally, store the calcium silicate boards in a dry, well-ventilated area to prevent moisture absorption, which can lead to dimensional changes and reduce their performance.

Cutting and Drilling

When cutting or drilling calcium silicate panels, please take precautions to minimize dust generation and protect yourself from respiratory issues. Please consider the following guidelines:

● Use a special saw or blade designed for cutting calcium silicate board.

● Always ensure that the calcium silicate boards are in good condition before proceeding with the installation.

● Keep the work area well-ventilated to disperse dust particles.

● Wear a suitable dust mask to prevent inhalation of dust particles, especially when working in confined spaces.

Fire Safety Measures

One of the key advantages of calcium silicate boards is their excellent fire resistance. To ensure proper fire safety when working with fireproof calcium silicate boards:

● Follow the manufacturer's guidelines for installation and ensure proper fire-rated assembly.

● Use fire-rated sealants and adhesives that are compatible with calcium silicate boards to maintain their fire resistance.

Moisture Management

While calcium silicate boards are resistant to moisture, excessive exposure to water can affect their performance. You need to pay attention to:

● Protect the waterproof calcium silicate boards from direct contact with water as possible during storage and installation.

● Ensure proper waterproofing measures are in place in areas prone to water, such as bathrooms, kitchens, or exteriors.

● Use appropriate sealants and coatings to protect the waterproof calcium silicate board edges and maintain their water-resistant properties.

Regular Maintenance

To ensure the longevity and optimal performance of calcium silicate boards, regular maintenance is essential:

● Inspect the calcium silicate boards periodically for any signs of damage, such as cracks or moisture infiltration.

● Address any issues promptly to prevent further damage or deterioration.

● Follow the calcium silicate board manufacturer's recommendations for cleaning and maintenance procedures.

Conclusion

With proper precautions in place, using calcium silicate boards can be a rewarding experience where you can ensure your safety, protect the integrity of the board and achieve a successful installation. By taking the right precautions, you can maximize the benefits of calcium silicate boards while maintaining a safe and efficient work environment.

Sanle is a professional manufacturer engaging in the research, development, production, sale, and service of fiber cement boards, calcium silicate boards, EPS cement panels, decorative cement panels, and wood grain fiber cement siding panels. Please feel free to contact us for more details.