Sanle Calcium Silicate Ceiling Board

Calcium silicate ceiling boards are building materials specifically designed for use in ceiling applications. They are composed of a combination of cement, silica, and reinforcing fibers, resulting in a sturdy and fire-resistant board. These boards are available in various sizes and thicknesses such as 5mm calcium silicate board, and 9mm calcium silicate board to suit different ceiling configurations.

Applications of Calcium Silicate Ceiling Boards

● Commercial Buildings

● Residential Buildings

● Educational Institutions

● Healthcare Facilities

● Industrial Settings

Calcium silicate ceiling boards offer a range of properties that make them suitable for use in both residential and commercial buildings. Their key characteristics include exceptional fire resistance, thermal insulation, durability, moisture resistance, and sound insulation.

Calcium Silicate Ceiling Board in Sanle

The raw material of the Sanle calcium silicate board is high-purity quartz flour, high-grade portland cement,high-purity slaked lime, plant fiber, and other mineral-added substances. Sanle calcium silicate board is for indoor partitions and ceilings of moisture-proof and fireproof in the wet area building for both civil and industrial applications.

Size

| Thickness(mm) | Width(mm) | Length(mm) | Weight(kg/pcs) |

| 5/6 | 595/603 | 595/603 | 3.5 |

Parameters

| Deviation in thickness: ±0.5mm | Density Density: 1100—1300kg/m3 |

| Bending strength: ≥ 12MPa(EMC) | Modulus of Elasticity: 7100±500MPa(Wet) |

| Moisture content: ≤ 10% | Wet expansion: ≤ 0.2% |

| Thermal Conductivity: ≤ 0.3W/(m.K) | Frost Resistance: -30 Celsius |

| Temperature resistance ±120 Celsius | Incombustibility A grade fireproof |

Features

● 100% Asbestos Free

● Fire Resistance and Moisture Resistance

● High Strength and Good Stability

● Anti-Fungus and Antiseptic

● Widely used in Partition and Suspension Systems.

● Easy working

● Anticorrosive

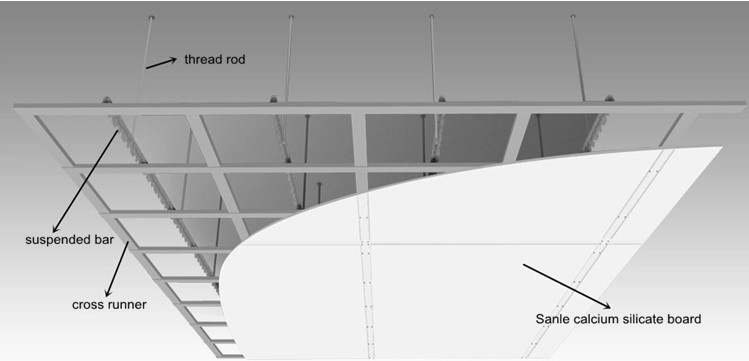

Ceiling Installation Method

Installation of calcium silicate ceiling boards is relatively straightforward due to their lightweight nature.

● Carry out ceiling line-measuring to determine the ceiling’s fixed position, the boom’s central range is generally 1200.

● Connect and fix the boom and main keel with a hanging piece to make the main keel keep the level position.

● Vertically fix the sub-keel to the main keel with a hanging piece; the sub-keel axis central range is 612mm.

● Install the laterally supporting keel properly, its central range is 1224mm.

● Fix the board on sub-keels with tapping screws, and to well the seam-connecting treatment.

Calcium silicate ceiling boards can be easily handled, cut, and shaped to fit different ceiling configurations, allowing for flexibility in design and ease of installation. This versatility enables architects and designers to create visually appealing and functional ceilings. Calcium silicate ceiling boards can be finished with various surface treatments to match the desired aesthetic of the space.

Notice

The hanging system of Sanle board combined with a light steel keel is divided into two kinds of person-standing type and non-person-standing type; for the non-person-standing type, only consider the self-weight of ceiling and light. Lamp without loading other loads; for the person-standing type. Consider about 80~100kg load when someone repaired it.